Tensile Strength Rating refers to the maximum tensile load a cable tie can withstand before failure. It is one of the most important mechanical performance indicators when selecting cable ties for electrical, industrial, or heavy-duty applications.

Higher tensile strength ratings are typically achieved through better raw materials (e.g., PA66 engineering nylon), larger cross-sectional dimensions, or reinforced structural designs. For specific applications such as automotive wiring harnesses or metal cable tying, performance requirements may vary significantly.

Table of Contents

ToggleWhy Tensile Strength Matters

Ensures reliable bundling under vibration and movement

Reduces failure during installation and long-term service

Supports compliance with OEM, UL, and industrial specifications

Critical for safety in electrical and mechanical systems

Low tensile strength can lead to premature breakage, resulting in wiring damage, system faults, or safety hazards.

Typical Tensile Strength Ranges

The following ranges are commonly referenced in the cable tie industry:

| Category | Tensile Strength Range |

|---|---|

| Miniature cable ties | 18–22 lbs (≈8–10 kgf) |

| Standard cable ties | 40–50 lbs (≈18–22 kgf) |

| Heavy-duty cable ties | 120–175 lbs (≈55–80 kgf) |

| Stainless steel ties | 200–350 lbs (≈90–160 kgf) |

These values may vary depending on certifications such as UL 62275, MIL spec, or automotive OEM requirements.

Testing Methods

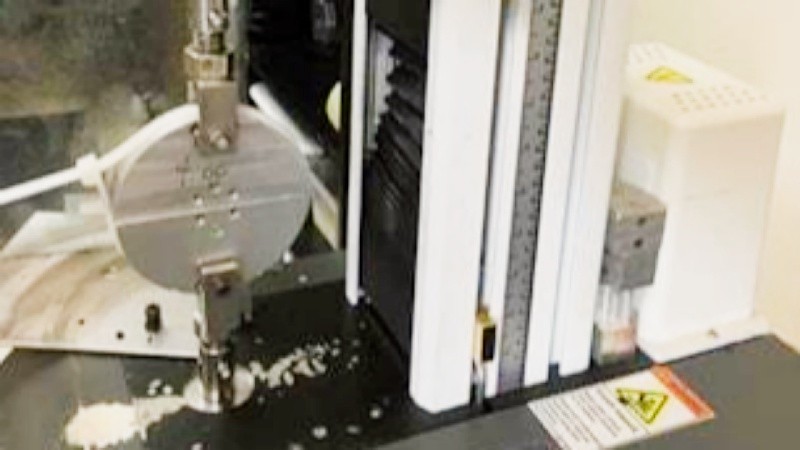

Tensile strength testing is performed using tensile testing machines, commonly according to:

UL 62275 Cable Management Standard

ISO/ASTM Mechanical Tensile Test Methods

Military & Automotive Specifications (Varies by OEM)

Samples are pulled at controlled rates until failure, with the highest load recorded as the tensile strength value.

Material Influence on Performance

Different materials produce significantly different strength profiles:

| Material | Tensile Performance | Notes |

|---|---|---|

| PA66 Nylon | Balanced tensile/impact | Used for most general cable ties |

| PA66 Heat-Stabilized | Improved retention at high temps | Automotive + engine bay usage |

| UV-Resistant Nylon | Better outdoor durability | Solar & construction |

| Stainless Steel 304/316 | Very high tensile strength | Industrial & fire-risk areas |

This makes Tensile Strength Rating a performance dimension that naturally connects to multiple materials and use cases.

Application Examples

Tensile strength ratings impact cable tie selection in:

Automotive wire harness fastening

Solar PV panel cable management

Industrial pipe and hose securing

HVAC & air duct installation

Electrical panel cable routing

Marine and offshore engineering

In these scenarios, insufficient tensile strength leads to fatigue failure, especially under vibration or heat.