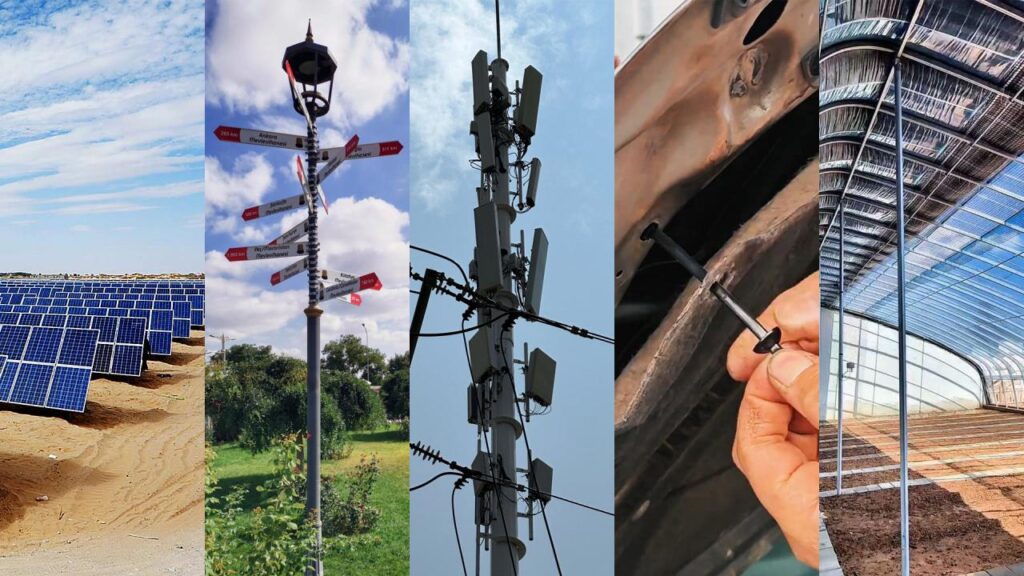

Industrial applications place far greater demands on cable ties than household or office use. In factories, power plants, construction sites, and infrastructure projects, cable ties must withstand harsh environments, heavy loads, extreme temperatures, and long-term exposure to chemicals or UV radiation.

Choosing the best cable ties for industrial applications is critical for safety, reliability, and maintenance efficiency. This guide explores the most suitable types of cable ties for industrial use, the materials they are made from, and how to select the right option for different environments.

What Makes a Cable Tie Suitable for Industrial Use?

Not all cable ties are designed for industrial conditions. Industrial-grade cable ties typically offer:

- High tensile strength

- Resistance to heat, UV, and chemicals

- Long service life

- Secure locking mechanisms

- Compliance with industry standards

The right cable tie depends on the specific working environment and application requirements.

Stainless Steel Cable Ties – The Heavy-Duty Standard

Stainless steel cable ties are widely considered the best option for demanding industrial applications.

Why stainless steel cable ties are ideal for industry:

- Extremely high tensile strength

- Excellent resistance to corrosion and chemicals

- Non-flammable and UV-proof

- Reliable performance in high-temperature environments

Common materials include 304 stainless steel for general industrial use and 316 stainless steel for marine, chemical, or coastal environments.

Typical industrial applications:

- Power generation facilities

- Oil and gas installations

- Chemical plants

- Marine and offshore equipment

- Heavy machinery cable management

For added protection, coated stainless steel cable ties are often used to prevent abrasion of sensitive cables.

Heavy-Duty Nylon Cable Ties for Industrial Environments

High-quality nylon cable ties are still widely used in industrial settings, especially where flexibility and cost efficiency are important.

Key features of industrial nylon cable ties:

- Good strength-to-weight ratio

- Flexible and vibration-resistant

- Easy and fast installation

- Available in UV-resistant and heat-resistant grades

Industrial-grade nylon cable ties are commonly used in:

- Control panels and enclosures

- Automotive manufacturing

- Electrical cabinets

- Machinery wiring

UV-stabilized nylon cable ties are essential for outdoor or sun-exposed industrial installations.

Heat-Resistant Cable Ties for High-Temperature Areas

In environments with elevated temperatures, standard nylon cable ties may soften or lose strength. Heat-resistant cable ties are designed for these conditions.

Typical materials include:

- Heat-stabilized nylon

- Special polyamides for high-temperature resistance

These cable ties are suitable for:

- Engine compartments

- Industrial ovens

- Manufacturing lines with heat exposure

They help maintain cable integrity where temperature fluctuations are frequent.

Flame-Retardant Cable Ties for Safety-Critical Installations

Fire safety is a major concern in industrial facilities. Flame-retardant cable ties are designed to slow flame spread and meet relevant fire safety standards.

Common applications include:

- Electrical substations

- Data centers

- Control rooms

- Public infrastructure

These cable ties are often required by regulations in safety-critical environments.

Metal-Detectable Cable Ties for Food and Pharmaceutical Industry

In industries such as food processing and pharmaceuticals, foreign object detection is essential. Metal-detectable cable ties are designed to be identified by detection systems.

They are commonly used in:

- Food production lines

- Pharmaceutical manufacturing

- Cleanroom environments

This helps reduce contamination risks and supports compliance with hygiene standards.

How to Choose the Best Cable Ties for Your Industrial Application

When selecting industrial cable ties, consider the following factors:

- Load requirements: Tensile strength needed for the application

- Environment: Indoor, outdoor, chemical exposure, or marine

- Temperature range: Operating and peak temperatures

- Regulatory requirements: Fire resistance, detectability, or compliance standards

- Installation method: Manual or tool-assisted

Using the wrong cable tie may lead to premature failure and increased maintenance costs.

Installation Best Practices for Industrial Cable Ties

- Do not overtighten, especially with nylon cable ties

- Use appropriate installation tools for stainless steel cable ties

- Avoid sharp edges and excessive vibration points

- Inspect cable ties regularly during maintenance

- Replace aging or damaged cable ties proactively

Proper installation extends service life and improves system reliability.

Conclusion

The best cable ties for industrial applications depend on the operating environment and performance requirements. Stainless steel cable ties are the preferred choice for extreme conditions, while industrial-grade nylon cable ties remain effective for many indoor and controlled environments. Specialized cable ties, such as heat-resistant or flame-retardant options, further enhance safety and durability in demanding industries.

Selecting the right industrial cable ties ensures long-term performance, safety, and cost efficiency across industrial systems.