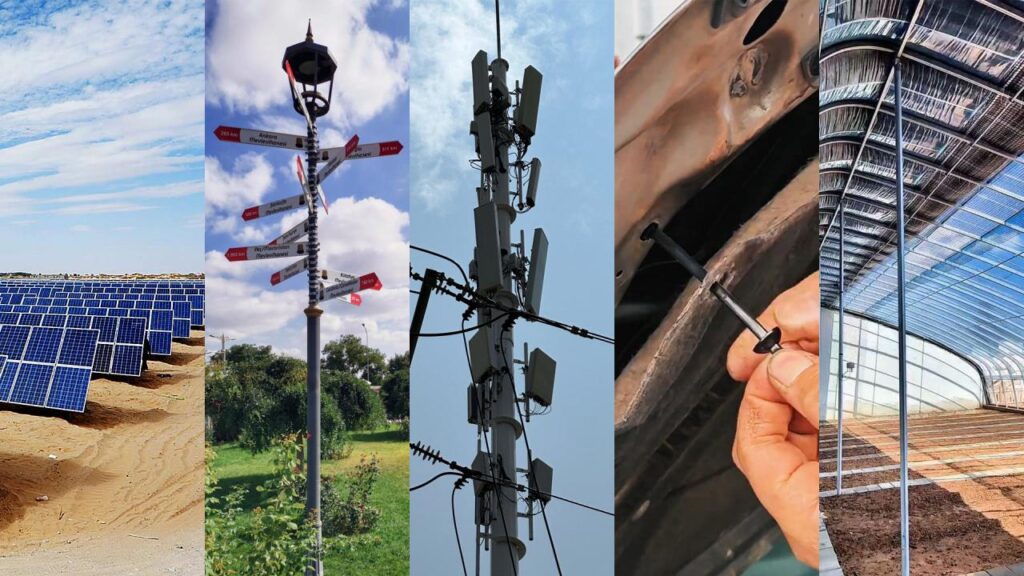

Selection Guide for Cable Ties Used in Outdoor Solar Installation

Outdoor solar installations operate in some of the most demanding environments for cable management. Long-term exposure to sunlight, temperature fluctuations, wind, moisture, and mechanical stress means that ordinary cable ties are often not suitable for photovoltaic (PV) systems. Selecting the right cable ties for outdoor solar installation is essential for system reliability, safety, and long service life. This guide explains how to choose the appropriate cable ties for outdoor solar projects, focusing on real installation conditions and practical selection criteria. Understanding Outdoor Solar Installation Environments Unlike indoor electrical systems, outdoor solar installations face continuous environmental stress. Common conditions include: Cable ties used in these environments must perform reliably for many years, often matching the lifespan of the solar panels themselves. UV Resistance: A Critical Requirement UV resistance is one of the most important factors when selecting ca

Value and Application of Green and Coloured Cable Ties in Site Management

In modern site management, organization, safety, and efficiency are critical. Whether on construction sites, industrial plants, warehouses, or electrical installation projects, cable management plays a surprisingly important role. Among the many small tools used on-site, green and coloured cable ties stand out as simple but highly effective solutions for visual identification, organization, and workflow optimization. While standard black or natural cable ties are widely used, coloured cable ties offer additional value that goes far beyond basic bundling. This article explores the practical value and real-world applications of green and coloured cable ties in site management. Why Colour Matters in Site Management Site environments are often complex, busy, and fast-moving. Multiple teams may work simultaneously on electrical wiring, plumbing, HVAC systems, data cabling, or temporary installations. In such conditions, visual clarity becomes essential. Coloured cable ties provide instant

How to Identify a High-Quality Cable Tie Manufacturer? Watch These Three Criteria

With countless cable tie suppliers available globally, identifying a truly high-quality cable tie manufacturer can be challenging. Product photos and low prices may look attractive, but they do not always reflect material quality, production capability, or long-term reliability. For distributors, project contractors, and industrial buyers, choosing the right manufacturer is critical to product performance, compliance, and customer satisfaction. This guide highlights three key criteria to help you evaluate and identify a high-quality cable tie manufacturer with confidence. Criterion 1: Material Quality and Production Consistency A reliable cable tie manufacturer starts with material control. Raw Material Selection High-quality cable ties are typically made from: Manufacturers using recycled or mixed-grade materials may offer lower prices, but this often leads to: A trustworthy manufacturer should be transparent about material sources and grades. Manufacturing Process Control Beyond mat

From Length to Width: Detailed Specs of Cable Ties and Selection Tips

Cable ties may look simple, but their performance depends heavily on correct sizing and specification. Choosing the wrong length or width can result in insufficient holding strength, poor durability, or even cable damage. For electrical, industrial, and outdoor applications, understanding cable tie specifications is essential. This guide explains cable tie dimensions in detail—from length and width to tensile strength—and provides practical selection tips to help users choose the right cable ties for different applications. Understanding Cable Tie Length Cable tie length refers to the total length of the tie when laid flat, usually measured in millimeters or inches. Length determines the maximum bundle diameter a cable tie can secure. Common cable tie lengths include: How to choose the right length: Shorter ties are suitable for small wire bundles, while longer ties are used for thick cables, pipes, or structural fastening. Cable Tie Width and Its Importance Width is one of the most c

How to Size an MCB for Home PV Systems

Correctly sizing an MCB (Miniature Circuit Breaker) is a critical step when designing or installing a home photovoltaic (PV) system. An undersized MCB may trip frequently, while an oversized one may fail to provide adequate protection, increasing the risk of cable damage or fire. This guide explains how to size an MCB for home PV systems, covering basic principles, calculation methods, and key safety considerations to help ensure reliable and compliant system operation. What Is an MCB and Why Is It Important in PV Systems? An MCB is a protective device designed to automatically disconnect a circuit in the event of overload or short circuit. In home PV systems, MCBs are commonly used on: The main purpose of an MCB is to protect cables and equipment, not the solar panels themselves. Key Factors That Affect MCB Sizing When selecting an MCB for a home PV system, several factors must be considered: Ignoring any of these factors may result in improper protection. Step 1: Determine the Maxim

What Is the Use of Cable Ties?

Cable ties, also known as zip ties, are simple fastening tools widely used to bundle, secure, and organize cables, wires, and other components. Despite their simple design, cable ties have become an essential accessory across many industries due to their versatility, ease of use, and low cost. From household organization to industrial installations, cable ties serve many practical purposes. This article explains the common uses of cable ties, where they are applied, and why they are so widely relied upon. Basic Purpose of Cable Ties The primary use of cable ties is to bundle and secure items together. Once tightened, a cable tie locks in place and holds objects firmly without loosening under normal conditions. Their one-way locking mechanism allows for: This makes cable ties an efficient solution for both temporary and long-term fastening needs. Cable Ties in Electrical and Wiring Applications One of the most common uses of cable ties is in electrical installations. Cable ties are use

What Are the Best Cable Ties for Industrial Applications?

Industrial applications place far greater demands on cable ties than household or office use. In factories, power plants, construction sites, and infrastructure projects, cable ties must withstand harsh environments, heavy loads, extreme temperatures, and long-term exposure to chemicals or UV radiation. Choosing the best cable ties for industrial applications is critical for safety, reliability, and maintenance efficiency. This guide explores the most suitable types of cable ties for industrial use, the materials they are made from, and how to select the right option for different environments. What Makes a Cable Tie Suitable for Industrial Use? Not all cable ties are designed for industrial conditions. Industrial-grade cable ties typically offer: The right cable tie depends on the specific working environment and application requirements. Stainless Steel Cable Ties – The Heavy-Duty Standard Stainless steel cable ties are widely considered the best option for demanding industrial appl

Solar Cable Ties – Reliable Cable Management for Solar Installations

Solar cable ties play a critical role in photovoltaic (PV) systems by securing and organizing cables in outdoor and high-exposure environments. Unlike standard cable ties used indoors, solar cable ties must withstand long-term sunlight, temperature fluctuations, moisture, and mechanical stress. Choosing the right solar cable ties helps improve system reliability, safety, and installation efficiency. This article explains what solar cable ties are, their key features, common materials, and how they are used in solar applications. What Are Solar Cable Ties? Solar cable ties are specially designed cable ties used in solar panel installations to fasten DC cables, grounding wires, and conduit systems to mounting structures. They are engineered for outdoor durability and long service life, often matching or exceeding the expected lifespan of solar panels. Compared to general-purpose cable ties, solar cable ties focus on: Long-1term stability UV resistance Weather durability Mechanical stren

What Are Cable Ties Made From?

Cable ties are widely used across industries, homes, offices, and outdoor environments to bundle, secure, and organize cables or components. Although they appear simple, cable ties are manufactured from different materials depending on their intended application, strength requirements, and environmental conditions. Understanding what cable ties are made from helps users choose the right type for durability, safety, and performance. This article explains the most common cable tie materials, their properties, and where each type is best used. Nylon (Polyamide) – The Most Common Material The majority of cable ties are made from nylon, also known as polyamide. Nylon cable ties are popular due to their flexibility, strength, and cost efficiency. Nylon 6/6 is the most widely used grade. It offers an excellent balance of tensile strength, elasticity, and resistance to abrasion. Key characteristics of nylon cable ties: Nylon cable ties are commonly used in: However, standard nylon may degrade

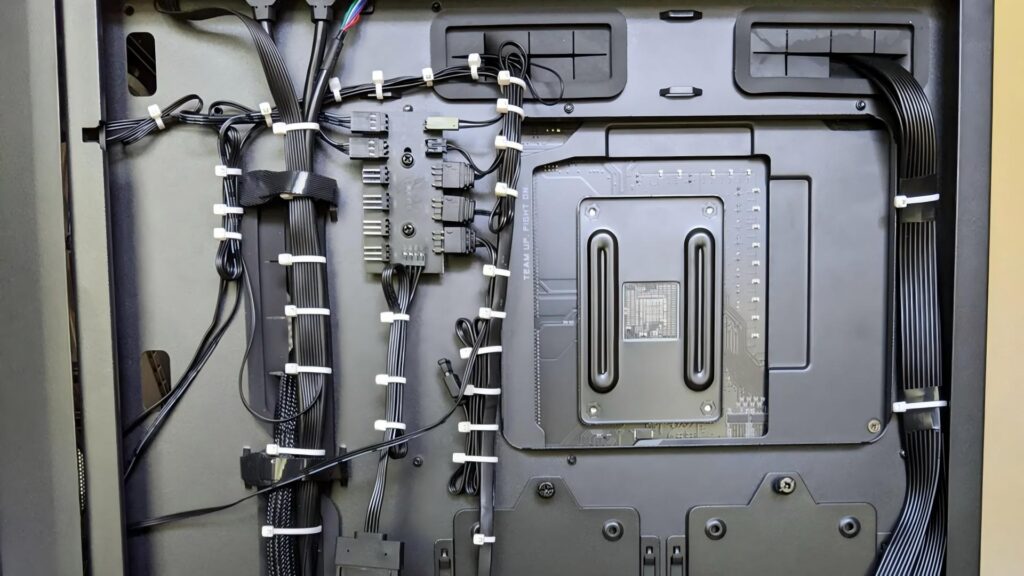

How to Zip Tie Computer Cables Properly

Messy computer cables are not only unpleasant to look at but can also cause airflow issues, make maintenance difficult, and increase the risk of accidental disconnections. Zip ties (also called cable ties) offer a simple and affordable solution for organizing computer cables at home or in the office. This guide explains how to zip tie computer cables properly, covering cable preparation, correct tying methods, and important safety tips to avoid damage to sensitive electronics. Why Zip Tying Computer Cables Matters Proper cable management provides several benefits: Whether you are managing a desktop PC, gaming setup, office workstation, or server cabinet, zip ties can help keep cables under control. Choosing the Right Zip Ties for Computer Cables Not all zip ties are suitable for computer cable management. The following factors are important: Material Nylon zip ties are the most common choice due to their flexibility and durability. Size Small zip ties (2.5 mm to 3.6 mm width) are idea