Buying the right nylon cable ties isn’t as simple as measuring the length and width of the items to be bundled. You also need to consider factors like usage conditions (allowing for a safety margin), price, material, UV resistance, temperature resistance, flame retardancy, and color. All of these factors will affect your ability to choose the right cable ties. Specialty nylon cable ties may be necessary in some cases, and it’s crucial to choose high-quality ties from ISO-certified manufacturers.

Table of Contents

ToggleSize Selection: Always Leave a Safety Margin

When choosing nylon cable ties, avoid selecting ties that are exactly the same size as the object being bundled. A common mistake is choosing ties that are too large for the wire harness or conduit, which significantly reduces locking strength and increases the risk of breakage. Recommended practice:

- Measure the maximum diameter of the object being bundled.

- Select a cable tie with a length 1.2-1.3 times the maximum diameter of the object.

Choosing the appropriate width is also important. For bundling heavier objects, requiring higher tensile strength, operating in vibration environments, or during long-term installations, wider nylon cable ties are necessary.

Tensile Strength: Match Strength to Application

The tensile strength of nylon cable ties refers to the maximum tensile force the cable tie can withstand before breaking. Choosing the right strength doesn’t mean the wider the better; this may lead to wasted resources and increased costs.

Recommended application scenarios for different cable tie models:

- Lightweight and mini cable ties: Signal cables, indoor wiring, wire harness marking, small wire harnesses;

- Medium and standard nylon cable ties: Electrical wiring organization, plastic flexible conduit organization, distribution panel fixing, tool fixing, etc.; these are also the most widely used cable ties.

- Heavy-duty cable ties and stainless steel cable ties: Industrial wiring, mechanical equipment, outdoor installation.

Also consider the application environment and site conditions, including static loads, dynamic stresses, and thermal expansion.

Material Quality: Nylon 6/6 Matters

Standard nylon cable ties are generally made of nylon 6/6, a material that balances strength, flexibility, and abrasion resistance. Some cheaper cable ties may use low-grade recycled nylon, which contains many impurities and typically leads to:

- Easily broken locks

- Tensile strength far below preset values

- Inconsistent color and performance between batches

- Cracking under no-load conditions

Especially for professional and commercial installations, you can confidently choose UHElectric, made from brand-new nylon 6/6 material, at the most competitive price on the market. Welcome to purchase!

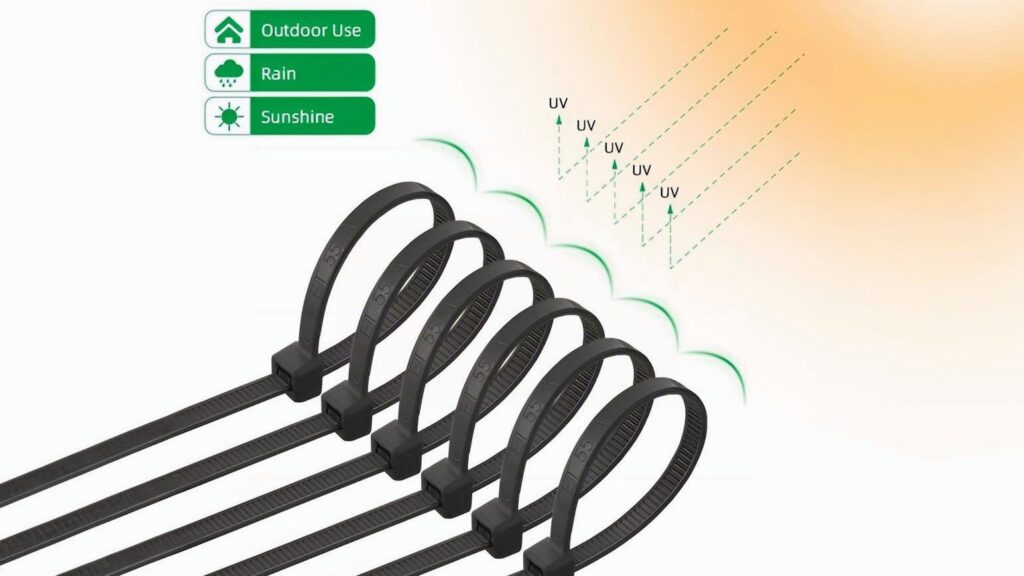

UV Resistance: Critical for Outdoor Use

Ordinary nylon cable ties are very prone to breakage after exposure to sunlight, becoming brittle or failing within a few months, and are generally only suitable for indoor use. This is not due to poor quality. For different applications, we add carbon black additives to the raw materials to improve UV resistance, creating UV-resistant nylon cable ties.

Applications of UV-resistant nylon cable ties:

- Solar installations: Fixing solar panels, combiner boxes, disconnect switches, or quick-shutdown devices, etc.;

- Outdoor wiring: Fixing distribution boxes, distribution cabinet wiring harnesses, fence fixing, sunshade cloth fixing, and cargo bundling;

- Construction sites: Material identification, tool fixing; Coastal or high-altitude environments.

Temperature Resistance: Know the Limits

Standard nylon cable ties typically operate in environments ranging from -40°C to +85°C.

- Excessively low temperatures will cause the cable ties to become brittle, like cookies, and break at the slightest touch.

- Excessively high temperatures will cause the cable ties to soften or deform completely.

For high-temperature environments such as engine compartments or industrial equipment, heat-resistant nylon cable ties should be selected.

Flame Retardancy: When Safety Compliance Is Required

Flame-retardant nylon cable ties are most widely used in electrical and industrial environments, meeting flame-retardant standards such as UL94 V-2 or UL94 V-0.

Flame-retardant nylon cable ties effectively reduce the spread of fire and are commonly used in control panels, data centers, or confined spaces.

Color Selection: More Than Appearance

Different colored cable ties not only indicate their color but also represent certain functional characteristics:

- Black Cable Ties: Best suited for outdoor and UV-exposed environments;

- Natural (white) Cable Ties: For indoor use, ensuring a clean and tidy environment;

- Colored cable ties: Used for classification or labeling.

Different colors require different materials, which means a slight increase in cost. Therefore, unless there are special uses or functional requirements, we recommend black and natural white nylon cable ties.

Special-Purpose Nylon Cable Ties

Specialized cable ties are used depending on the environment and application requirements. For example:

- Removable or reusable nylon cable ties are used for temporary securing.

- Metal-detectable cable ties are used in food processing.

Weather-resistant and salt spray- and chemical corrosion-resistant ties are commonly used in coastal or high-humidity environments.

These are more like custom-made products and should only be selected when there is a genuine need.

Manufacturer and Certification

Consistency in quality is crucial for large-scale projects. Reputable manufacturers with ISO certification ensure a stable supply of raw materials, standardized production processes, and batch sampling for tensile strength and locking performance testing.

Low-cost, uncertified suppliers may offer attractive prices, but this often involves gambling with the entire project lifecycle.

Conclusion

Choosing the right nylon cable ties requires considering not only the size of the items being bundled, but also their intended use and a manufacturer with stable production capabilities.

Loosen a Cable Tie (Safely & Cleanly):

- Method 1: Cut the cable ties using appropriate tools

- Method 2: Loosen the reusable cable tie.

Loosen a Cable Tie (Without Cutting It):

- Method 1: Use a flathead screwdriver

- Method 2: Longer fingernails

How to Cut a Cable Tie (Without Damaging Wires):

- Best tools

- Avoid

- Technique

In theory, nylon cable ties are disposable and can be reused. However, we can use techniques to completely loosen them.

Cheap nylon cable ties are usually made with cheap raw materials and cheap molds. We should choose cable ties with reasonable prices by identifying qualified manufacturers.